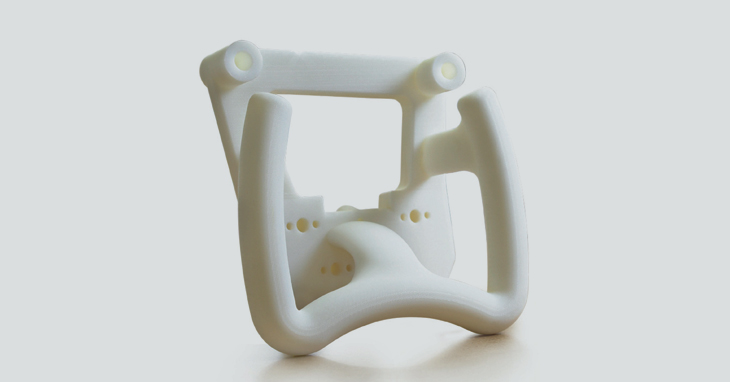

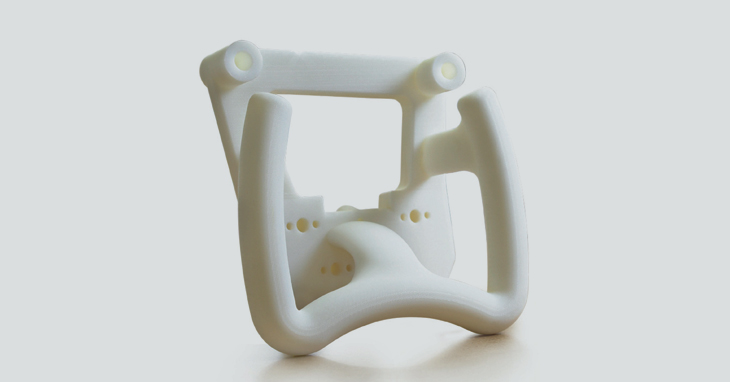

Jigs and Fixtures: More Profitable Production

Deliver real value to manufacturers with 3D printing. Tooling has always been one of the most expensive and time-consuming processes in the production cycle, not anymore.

3D printing has made it possible to create production tools without the costly process of tooling.

3D printing has moved beyond prototyping. The current state of 3D printing systems, materials and parts-on-demand providers makes 3D printing jigs and fixtures and other manufacturing applications practical and accessible to manufacturers.

Mainstream manufacturers are wise to seize on the economic and efficiency advantages offered by this technology, as well as the new possibilities it opens

PLease Kindly provide the details of your enquiry below

and we will endeavor to get back to you as soon as possible

White Paper

White Paper

Deliver real value to manufacturers with 3D printing. Tooling has always been one of the most expensive and time-consuming processes in the production cycle, not anymore.

White Paper

White Paper

3D printing is becoming a part of the game plan for those is the aerospace industry. Learn more how is stacks up against traditional manufacturing in our whitepaper

Case Study

Case Study

From the start, the Boom team knew 3D printing was going to play a crucial role in the development of XB-1, and ultimately for Overture. Download whitepaper to know more.