Jigs and Fixtures: More Profitable Production

Deliver real value to manufacturers with 3D printing. Tooling has always been one of the most expensive and time-consuming processes in the production cycle, not anymore.

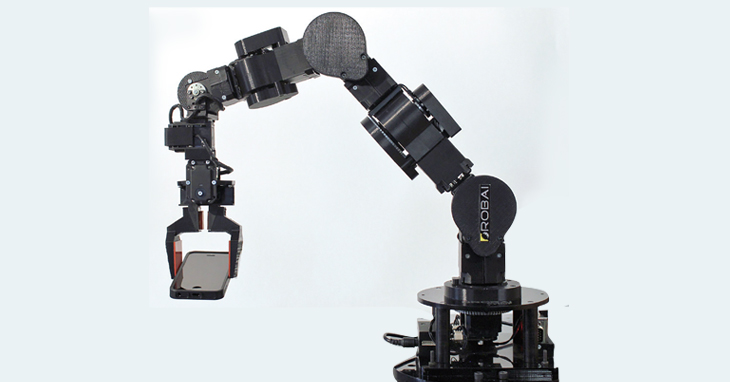

FDM® technology is increasingly used to create final production parts, particularly in the aerospace and automotive industries. The durable but lightweight nature of FDM materials make them well-suited for industrial applications, and the FDM design process is ideal for applications that require custom part designs.

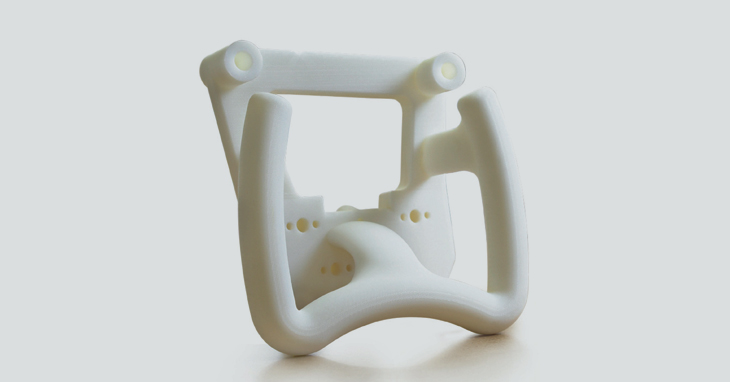

However, a barrier preventing the adoption of FDM for some production parts is its surface finish. Due to the nature of additive manufacturing, parts produced with FDM have visible build lines and surface inconsistencies. This is acceptable for most applications, but is undesirable for parts that require a smoother and/or more aesthetic finish. However, techniques are available to mitigate this surface roughness. These techniques optimize the appearance of parts and allow companies to use FDM technology to its maximum potential.

PLease Kindly provide the details of your enquiry below

and we will endeavor to get back to you as soon as possible

White Paper

White Paper

Deliver real value to manufacturers with 3D printing. Tooling has always been one of the most expensive and time-consuming processes in the production cycle, not anymore.

White Paper

White Paper

3D printing is becoming a part of the game plan for those is the aerospace industry. Learn more how is stacks up against traditional manufacturing in our whitepaper

Case Study

Case Study

From the start, the Boom team knew 3D printing was going to play a crucial role in the development of XB-1, and ultimately for Overture. Download whitepaper to know more.